Revolutionizing Melting Furnace Emission Control

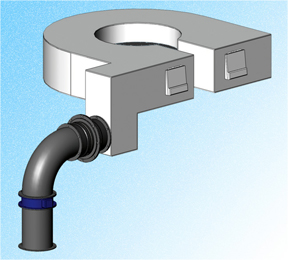

Tired of struggling with costly and inefficient furnace emission control? At IVT Engineering, we have developed a unique solution that delivers exceptional results while dramatically cutting costs. Our innovative enclosing hoods provide a comprehensive solution for a variety of metal furnaces, from electric induction to crucible.

Tired of struggling with costly and inefficient furnace emission control? At IVT Engineering, we have developed a unique solution that delivers exceptional results while dramatically cutting costs. Our innovative enclosing hoods provide a comprehensive solution for a variety of metal furnaces, from electric induction to crucible.

The IVT Difference: Performance, Savings & Safety

Our enclosing hood system is engineered for close capture, a method that requires less exhaust volume to achieve superior results. This innovative approach translates into three key advantages for your business:

- Dramatic Cost Savings:

- Lower Capital Costs: Our unique design saves you tens of thousands of dollars on ductwork, foundations, and structure.

- Reduced Energy Costs: Lower exhaust volume requirements mean less energy consumption.

- Less Maintenance: The design is built for durability and ease of maintenance, providing long-term savings.

- Superior Performance:

- Total & Continuous Control: Our hoods provide complete emission control during charging, melting, and pouring activities.

- Effortless Slag Removal: A separate exhaust system is not needed for the slag-removing process.

- Seamless Pouring: The system continues to control emissions even when the furnace tilts for pouring.

- A Safer Workplace:

- Clean Air: High volumes of contaminants are captured at the source, preventing them from spreading and improving the work environment.

Applications:

Our unique system is suitable for a wide range of industries, including foundries, smelters, steel mills, and more. We are committed to providing the service you need for a successful and reliable project.

Let's discuss how we can help you achieve better emission control with less cost. Our engineers are ready to advise you on the best solution for your facility.